Data Science Case Study for a European Flow Technology Company

Summary

The VCreate team was called upon by a European Flow Technology company to conduct a cost analysis of all their foundry suppliers.

Background and Business Problem

This Flow Technology manufacturer had a very specific demand for castings with impeccable finish, pressure tightness till 15 Bar and absolute freedom from sand inclusions and other metal defects. Their overall annual purchase of castings ranged between $2 million and $2.5 million. However, this demand was spread out over 100 different components making it difficult for any mechanized foundry to meet their quality standards and rigid delivery schedules. With great difficulty, this flow technology company managed to purchase the required material from two vendors. However, this increased reliance led to higher costs which started hurting the bottom line. Profit declined by nearly 200 basis points. Moreover, plans indicated doubling volumes in five years. This would lead to major supply constraints.

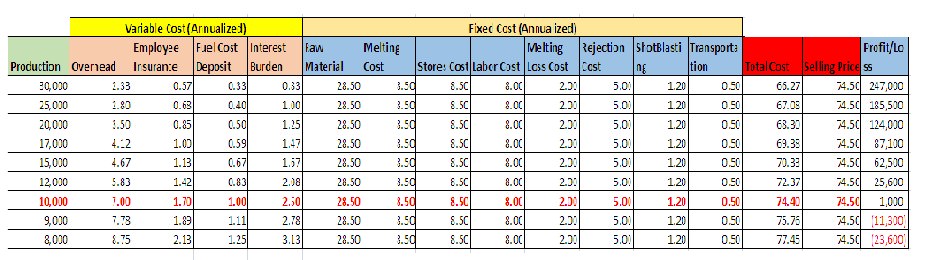

The team conducted a cost analysis of the vendors. Gaurav Shah led a team of data analysis and foundry experts. This exercise started with a visit to all vendors to collect all production data and financial data. Gaurav Shah supervised data accumulation, data assimilation and averaging data taking into account all variables over a five year period.

Outcome

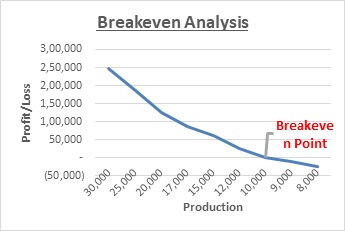

After an extensive exercise, the VCreate team presented their findings in the form of reports and charts. The aim of this exercise was to determine exact costs borne by the vendor, thereby determining their net margins which would enable the purchase official to effectively negotiate prices. Moreover, this would enable the purchase team to set up new vendors and consequently remove supply constraints.

If you found this data science case study interesting, watch this space for more of such updates!